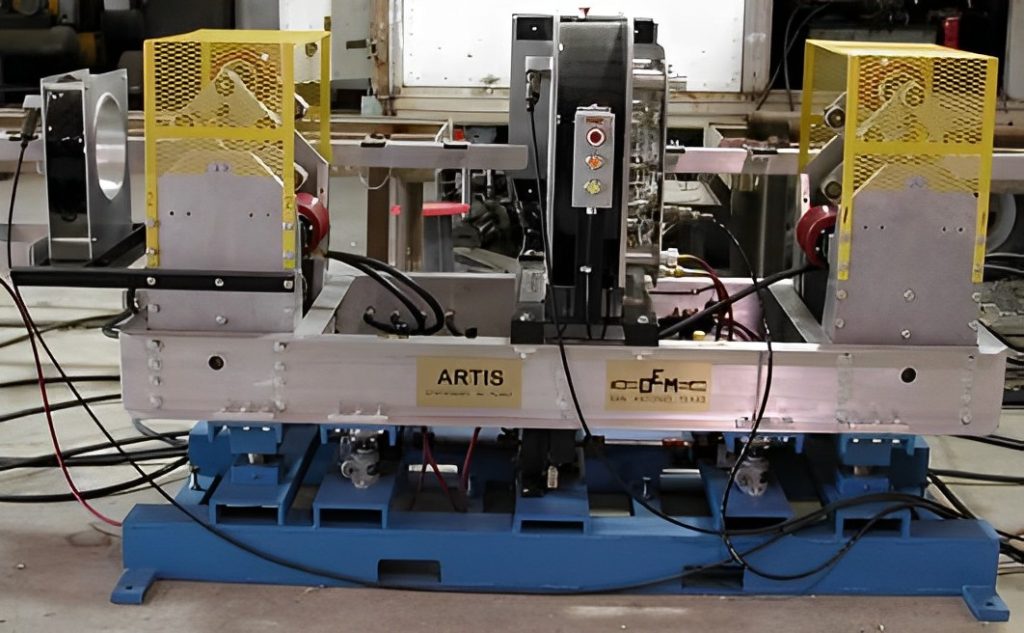

The ARTIS-5 Pipe Inspection System provides high speed state-of-the-art inspection for defects located in used Oil Field Drill Pipe, Tubing and Casing.

The ARTIS-5 is the most technologically advanced 5-function system available, designed to detect more defect types than any other EMI system in the marketplace.

The ARTIS-5 is the only five function ST EMI inspection unit available !

•

•

•

•

•

•••••Two Models Available: 5400 and 5500. See below for details!

ARTIS EMI Systems are the ONLY systems in the industry which inspect 100% of the wall surface using magentic wall loss methods. All other systems inspect less than 20%!

KEY Features:

- OEM’s PATENTED Methods & Technology.

- Automated Inspection System for High Volume Production!

- 100% computer controlled. No knobs to turn – ever !

- Superior defect repeatability.

- 100% High Resolution Solid State Sensor System for the most sensitive EMI inspection capabilities available.

- Automatically calibrates in seconds or manual operator calibration.

- Fast inspection speed – up to 140 FPM (43 MPM).

- Engineered to be rugged, extremely easy to use and maintain.

- MODEL-5400: 2-3/8″ through 6-5/8″ O.D. API tubular products can be inspected.

- MODEL-5500: 2-3/8″ through 13-3/8″ O.D. API tubular products can be inspected.

- Competitive spare parts / maintenance costs – The BEST inspection results for a comparable maintenance cost!

- More than 100% circumferential coverage for suspected Transverse Flaws

- More than 100% circumferential coverage for suspected Localized Wall Loss such as corrosion pitting, flux leakage technology.

- More than 100% circumferential coverage for suspected Localized Wall Loss such as erosion, flux density technology.

- Includes our “thick-thin” wall thickness monitoring function for large area wall loss defects such as OD wear, rod wear and gradual wear.

- Electronically detected longitudnally oriented SPLITS usually occurring from areas of internal rod wear in used production tubing.

- On Board Diagnostics (O.B.D.) system. The Second Generation of our proprietary solid-state real time monitoring system for necessary components.

- For a field portable configuration, see our ARTIS-3 Portable unit.

- Computer Controlled Demagnetizing System.

- Optional loading / unloading functions.

- Optional defect paint marking system.

- . . . and much more !

This product and / or it’s use may be covered by one or more United States Patents.