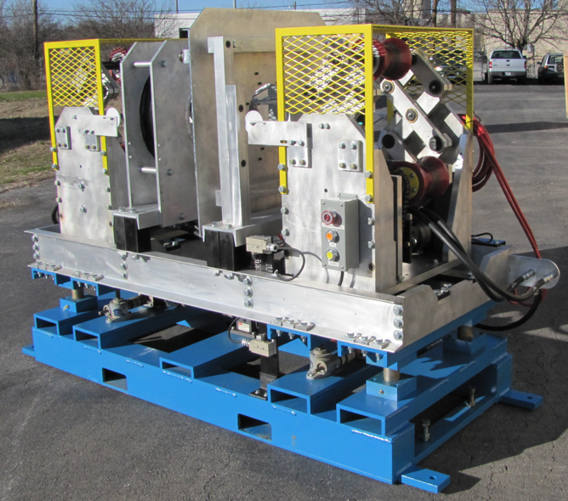

The MODEL-4500 EMI Pipe Inspection System provides high speed detection for THREE (3) independent defect groups in NEW or USED Oil Field Drill Pipe, Tubing and Casing.

The MODEL-4500 system provides the most economical inspection solution with three (3) unique EMI inspection funcitons.

The MODEL-4500 systems include an Advanced system design.

FUNCTION (defect types)

1. Transverse Flaws (for holes, cracks, sharp pits)

2. LARGE Localized Wall Loss (larger ID and OD erosion/corrosion)

3. Full Length Wall Thickness Monitor (cross sectional area)

TECHNOLOGY

1. Flux Leakage

2. Flux Density

3. Flux Density

KEY Features:

- 100% computerized system. No knobs to turn – ever!

- Superior defect repeatability.

- Transverse Flaw Detection using Induction search coils.

- Localized wall loss feature implements non-contact solid state Hall sensors. Non-contact design provides a Lower Total Cost of Ownership by eliminating wear and tear!

- Fast inspection speed – up to 140 FPM.

- Engineered to be rugged, extremely easy to use and maintain.

- API tubular products up to 13-3/8″ O.D. can be inspected (model dependent). Specifiy size range when ordering.

- More than 100% circumferential coverage for suspected Transverse Flaws.

- 360 Degree coverage for localized Wall Loss (pitting, erosion and corrosion) and Thick-Thin Wall Monitoring feature, cross sectional area monitor.

- Solid State Meter (S.S.M.) Technology derived from our ARTIS series of products. The digital meters never need calibration!

- Computer Controlled Demagnetizing System.

- Optional loading / unloading functions.

- Optional defect paint marking system.

- . . . and much more !

This product and / or it’s use may be covered by one or more United States Patents.